- solution

- Product center

- event

- Agent network

- Serve

- about us

- contact us

- 中文

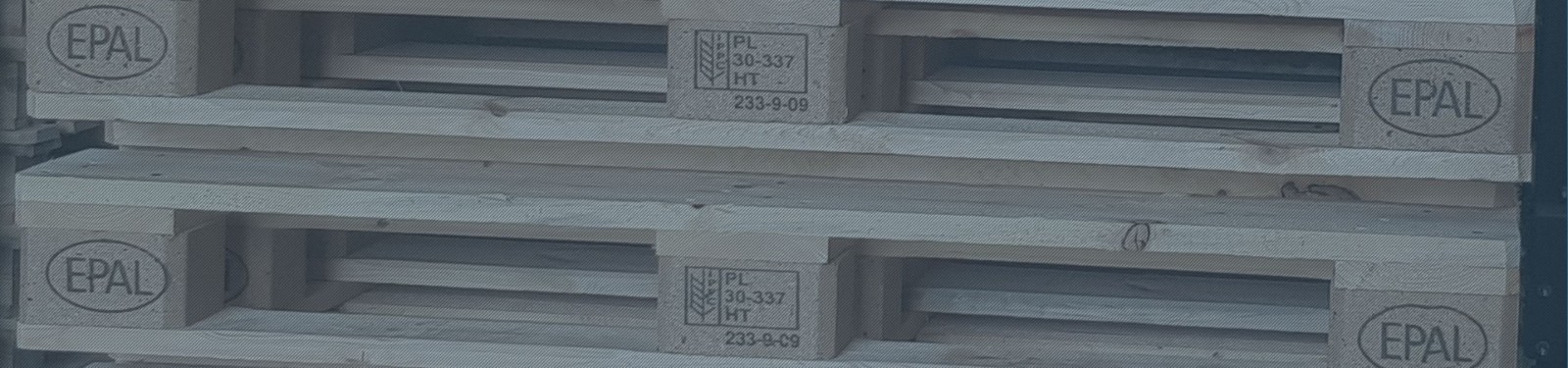

The tray has been used as a means of transportation and storage in logistics, which is used worldwide and has become indispensable. They optimize transportation, stored in narrow spaces and loading of stacked cargo. Sometimes they are disposable trays, sometimes being reusable trays. Sometimes they are made of wood, sometimes they are made of plastic, corrugated board or steel. There are many varieties, and this is also true for tray markings.

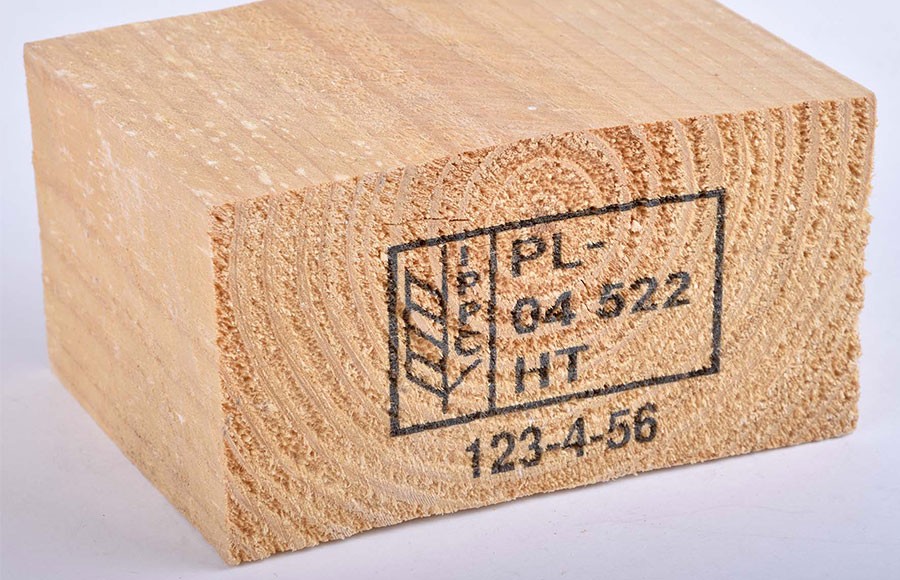

Pallets are marked by an inkjet printer.

Pallets are marked by an inkjet printer.Pallets must be legible and tamper-proof.This can be achieved by marking pallet blocks manufactured in different shapes, sizes and numbers.Pallets block provides information (IPPC marking) about the organization that made the pallets or whether the pallets are vermin free.In addition to the standard required pallet markings, alphanumeric information or manufacturer logos can be found on pallet blocks.根据要求,用于托盘标记的打印内容也会有所不同。

In order to respond quickly to changing print content, a flexible marking system is needed.REA by developing new(Tray application)This requirement is met precisely。Small, order-related print jobs and large volumes can be flexibly marked with the software extension of The Blue GK 2.0PA - regardless of pallet type.

To do this, the number of blocks to mark and print content to print are stored on the controller.After a successful print, the next tray or print job of the same series is followed.If printing is not triggered for each block and therefore the number of blocks defined is not marked, you can choose to signal to stop the conveyor belt system.In this way, the software ensures that only perfectly and clearly marked pallets are produced.

Inkjet printerAnother solution is provided,It features maintenance-free ink cartridge based printing technology.Using this coding and labeling system, print contents up to 50.4 mm print height (12.7 mm per print head) can be applied directly to absorbent surfaces in a clean, environmentally friendly and solvent free manner.