- solution

- Product center

- event

- Agent network

- Serve

- about us

- contact us

- 中文

Today, high-precision laser welding processes are increasingly used as alternative to plastic ultrasonic and high frequency welding.

Prerequisites are reliable and economically applied composite additives. In the past, there was no industrial solution. LION TEC and partners have developed a very interesting digital printing process that implements automation using LION TEC Clearweld Primer.

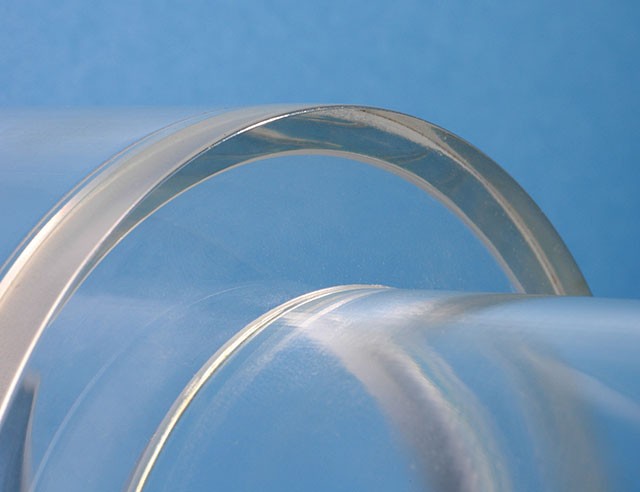

Traditional transparent plastics, such as PE, PP, PC, PS, SAN, naturally only limited laser absorption capacity, making plastic welding impossible or very difficult. Using a blue solution, a transparent and laser transparent plastic material can be prepared with a high-than-laser energy, so that they can be welded with laser. Injection molded plastic parts and nonwoven fabrics can also be welded using this solution.